Textile Technology Innovation Through Sustainability

In the rapidly developing 21st century, sustainable development has become a global consensus. Against this backdrop, Annie’s Smartex is committed to developing and producing more environmentally friendly and sustainable textile raw materials, contributing to the future of our planet.

Our Vision

We aim to create a green, sustainable textile ecosystem. We believe the textile industry is not just a commercial activity, but an important exploration of harmony between humans and nature. Our textile raw materials should come from sustainable, eco-friendly resources, with production processes that minimize environmental impact, and products that can be effectively recycled and reused. Our goal is to make sustainable textiles the new industry norm and green the foundation of textile products through continuous innovation and practice.

Our Mission

To realize this vision, we have three key missions:

Promote innovative applications of natural biomaterials: We actively research and develop pure natural biomaterial extraction technologies, transforming renewable resources into high-quality textile raw materials. For example, we process pineapple leaves, a common production waste, into 100% natural pineapple leaf fiber, achieving both environmental and economic benefits. We are committed to promoting the widespread application of such materials, reducing dependence on fossil resources, and lowering carbon emissions in production.

Develop biodegradable chemical fibers: Addressing the issue of traditional chemical fibers’ poor degradability, we invest heavily in developing biodegradable alternatives. Our EarthGuard® 100% Biodegradable yarn decomposes faster, reducing environmental impact. This fiber maintains excellent performance while rapidly degrading in natural environments, minimizing soil and water pollution.

Achieve circular utilization of chemical fibers: Recognizing resource limitations, we focus on developing recyclable chemical fibers. Our PECooX® 100% Recycled Polyethylene (HDPE) Fiber improves resource efficiency and reduces environmental impact. Through advanced recycling and regeneration technologies, we transform waste textiles into new raw materials, achieving resource circularity, reducing production costs, and minimizing environmental pollution.

Our Values

In pursuing sustainable development, we adhere to the following values:

Green Ecology: We prioritize environmental protection and sustainable development, committed to promoting the green transformation of the textile industry. We advocate for renewable, biodegradable materials and reducing pollution and energy consumption in production.

Innovation-Driven: We recognize innovation as key to sustainable development. We continuously invest in R&D, exploring new materials, technologies, and processes to drive textile industry upgrade and transformation.

Responsibility: As members of the textile industry, we bear responsibility for the planet and humanity. We integrate this sense of responsibility into our daily work, ensuring our products, technologies, and services meet environmental and sustainability requirements.

Collaborative Win-Win: We believe cooperation leads to mutual success. We work closely with upstream and downstream partners to promote sustainable development in the textile industry. We also actively collaborate with government departments, industry associations, and social organizations to promote the industry’s green transformation and upgrade.

On the path of sustainable development, we remain true to our original aspirations and forge ahead. We look forward to working with you to create a green, sustainable textile future!

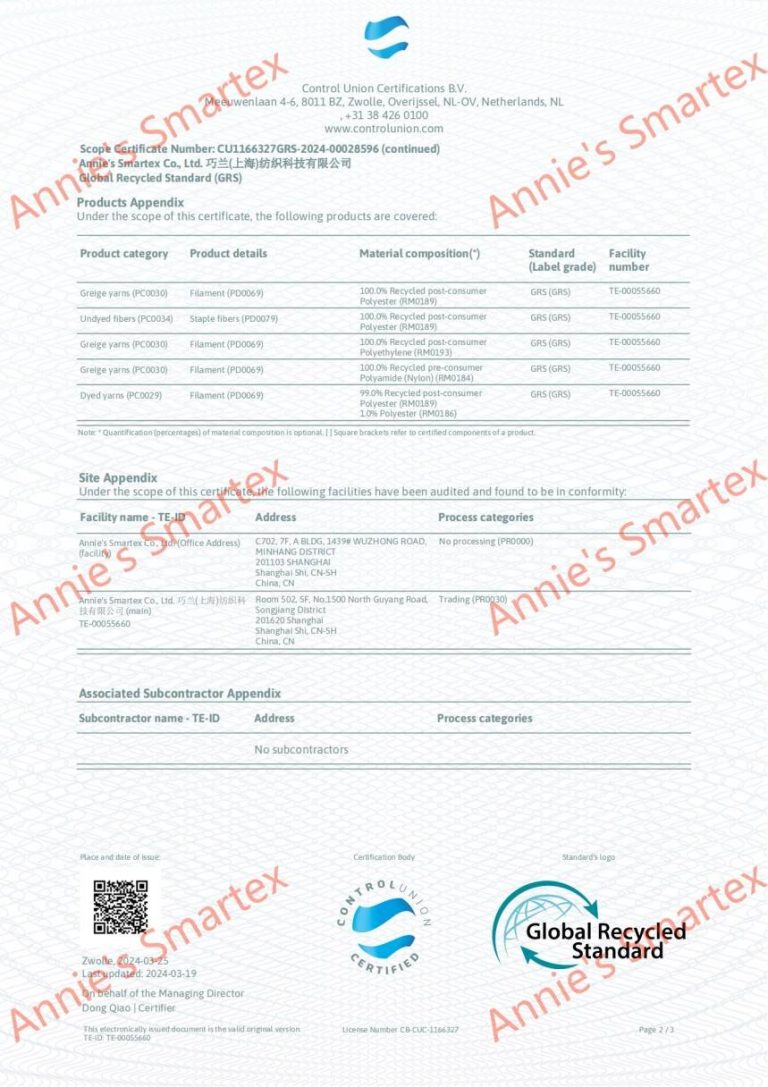

We renew our GRS(Global Recycling Certification) certificate every year. It’s an international, voluntary, and comprehensive product standard that establishes third-party certification requirements for recycling contents, production and marketing chains of custody, social responsibility and environmental practices, and chemical limits. GRS aims to increase the use of recycled materials in products and reduce/eliminate the hazards caused by their production by addressing supply chain manufacturers’ management and control of product recovery/recycling components, chain of custody, social responsibility and environmental norms, and the enforcement of chemical restrictions.