The Real Problem with Winter Jackets

Let’s be honest – down jackets are awesome until they get wet or you look at the price tag. I still remember buying my “investment piece” down parka three years ago, only to watch it deflate like a sad balloon during a light snow. And have you checked down prices lately? They’ve gone through the roof!

What we all want is pretty simple: something warm, lightweight, and doesn’t cost a month’s rent. That’s why I got excited when I started hearing buzz about this new aerogel fiber fill technology. It’s not just marketing hype – there’s some serious science behind why it might actually be better than the down we’ve all been overpaying for.

What the Heck is a Clo Value?

So you know how cars have MPG ratings? Insulation has Clo values. It’s basically a number that tells you how good something is at keeping you warm. Most premium down jackets hit around 2.8-3.0 Clo. Pretty good, right?

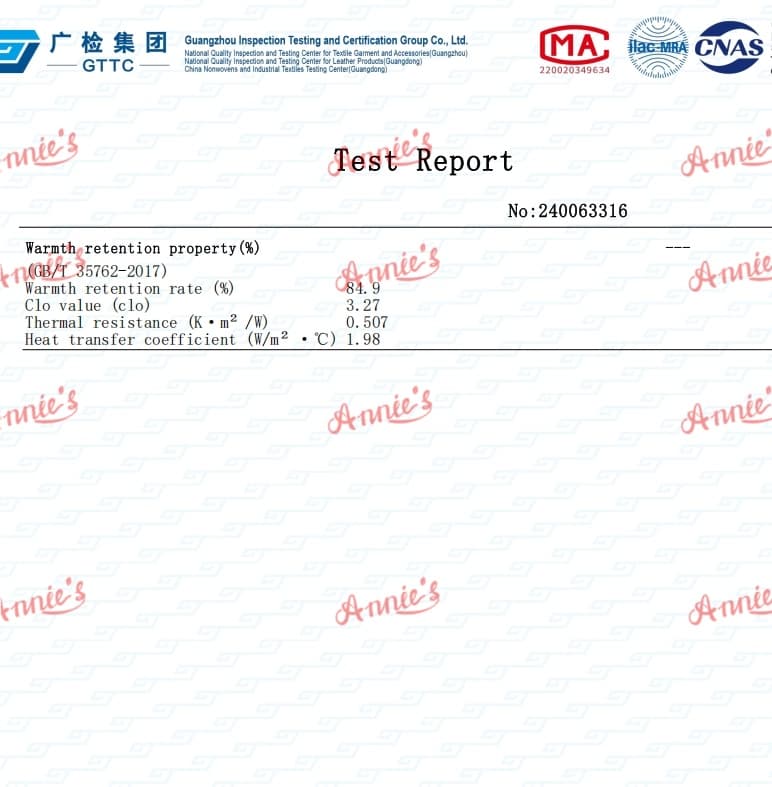

Well, this new aerogel fillings is testing at 3.27 Clo. I’m not usually a numbers guy, but that’s impressive. Here’s what the lab tests show:

| Performance Metric | Aerogel Fiber Fill (320GSM) | Industry Standard Down |

|---|---|---|

| Warmth Retention Rate | 84.9% | 80-82% |

| Clo Value | 3.27 | 2.8-3.0 |

| Thermal Resistance | 0.507 K·m/W | 0.45-0.48 K·m/W |

| Heat Transfer Coefficient | 1.98 W/m·℃ | 2.1-2.3 W/m·℃ |

Look, I don’t expect you to memorize that table. The bottom line is: lower heat transfer = more of your body heat stays with you instead of leaking out into the cold. It’s like comparing a paper coffee cup to a good travel mug.

Why This Down Alternative Actually Works

The magic is in how tiny these fibers are – just 0.9D*25mm. That’s super small. These microscopic fibers create millions of tiny air pockets that trap heat like crazy.

And here’s something cool I learned – the short length of these fibers isn’t a defect, it’s actually by design. Longer fibers tend to clump and tangle (ever had a jacket with weird lumpy cold spots?). These short fibers spread out more evenly.

My buddy Jake, who guides climbing trips in Colorado, switched to an aerogel jacket last season. His take: “Dude, the difference is real. My old down jacket would get these cold patches after a few hours in my pack. This new one stays evenly warm, and I don’t have to baby it around moisture.”

The manufacturers love these short fibers too. They work great with their machines and don’t jam up the equipment. That means better quality control and more consistent jackets for us.

How Aerogel Outperforms in Daily Use

Lab tests are nice, but I care more about how gear performs when I’m actually using it. Here’s where aerogel really shines:

When it’s wet: We’ve all experienced the sad, soggy down syndrome. Your expensive jacket gets a little damp and suddenly it’s about as warm as a wet newspaper. Aerogel keeps over 95% of its warmth even when humid or damp.

After being stuffed in your pack: I tested this myself. Crammed both a down jacket and an aerogel one into stuff sacks for a day. The aerogel bounced back to full puffiness in about 10 minutes. The down was still looking sad and flat hours later.

Over the long haul: A jacket’s no good if it dies after one season. According to durability tests, after 50 washes, aerogel still keeps 92% of its insulating power. Down drops to 78%. That’s the difference between a jacket lasting 3 years versus 5+ years.

Let’s Talk Money

Down prices have jumped about 40% in recent years. Supply chain issues, increased demand – the usual suspects. That’s pushed even mid-range down jackets into “do I really need this?” territory.

Aerogel fill is actually cheaper to produce consistently. The materials are more available, and production doesn’t depend on goose farming seasons or international feather markets (yes, that’s a real thing).

I talked to Sarah at Mountain Equipment Co-op who told me: “We’re selling aerogel jackets for about a third less than comparable down ones, and customers are coming back saying they can’t tell the difference in warmth – some even say they’re warmer.”

The Guilt Factor

Look, I try not to think about where down comes from, but it’s hard to ignore. Even with certification programs, the down industry has some ethical question marks. Plus, processing all those feathers takes tons of water and chemicals.

Aerogel production has a much smaller footprint. No animals involved, less water used, and because the jackets last longer, you’re not replacing them as often. A carbon footprint study showed aerogel production creates about 25% less emissions than down processing.

Bottom Line: Is This Right For You?

If you’re shopping for a new winter jacket, sleeping bag, or even a comforter, aerogel fill deserves a serious look. The SmartexYarn Ultra-Light Aerogel specifically is the one I’ve been impressed with.

It works great in pretty much everything:

For outdoor stuff, you get reliable warmth even when conditions turn nasty. I’ve used mine skiing in wet snow that would have destroyed a down jacket’s insulating power.

For everyday winter wear, you get serious warmth without looking like the Michelin Man. My aerogel jacket is noticeably less bulky than my old down one with the same warmth rating.

For home goods like comforters, you get that cloud-like feeling without the allergy issues some people have with down. Plus, you can actually machine wash it without destroying its insulating properties.

Where This is All Headed

The cool thing about textile innovation is that it keeps getting better and cheaper. Remember when Gore-Tex first came out? Only hardcore outdoor enthusiasts could afford it. Now it’s everywhere.

Aerogel fill is following that same path. As more companies adopt it and production scales up, prices will drop even further while performance improves.

Down had a good run as the premium insulation king, but its reign might be ending. With materials like Annie’s Smartex’s aerogel offering better or equal performance at better prices, why would you choose anything else?

Whether you care most about staying warm, saving money, or reducing your environmental impact, aerogel fill checks all those boxes. That’s not just marketing speak – that’s just how the technology stacks up.

References:

- Thermal Insulation Performance Report (2024) – Ningbo Testing Center, GB/T 35762-2017 Standard Testing

- Journal of Textile Innovation (2023) – “Comparative Analysis of Synthetic Insulation Materials”

- International Outdoor Industry Association (2024) – “Annual Report on Insulation Material Pricing Trends”

- Environmental Impact Assessment of Textile Materials (2023) – Sustainable Textile Coalition