Every year, thousands of motorcycle riders face a common yet serious risk – road rash injuries. Studies show that approximately 88% of motorcycle accidents result in some form of abrasion injury, with severe cases requiring extensive medical treatment and prolonged recovery periods. The average cost of treating severe road rash injuries can exceed $25,000, not including lost work time and rehabilitation expenses. [3]

When you’re cruising down the highway or navigating challenging terrain, your protective gear is your only defense against the unforgiving asphalt. Traditional motorcycle clothing often compromises between protection and comfort, leaving riders vulnerable to serious abrasion injuries that can occur at speeds as low as 30 mph. Modern riders need gear that doesn’t force them to choose between safety and comfort. [2]

Understanding the Protection Challenge

The severity of road rash injuries is directly related to the quality of protective clothing. According to motorcycle safety standards (CE EN 13595), protective clothing must withstand specific abrasion resistance tests that simulate real-world accident conditions. These tests measure how long materials can withstand dragging across abrasive surfaces at high speeds – a crucial factor in preventing serious injuries. Recent studies indicate that conventional materials lose up to 60% of their protective capabilities after just six months of regular use. [2]

UHMWPE Yarn: A Advanced Protective Material

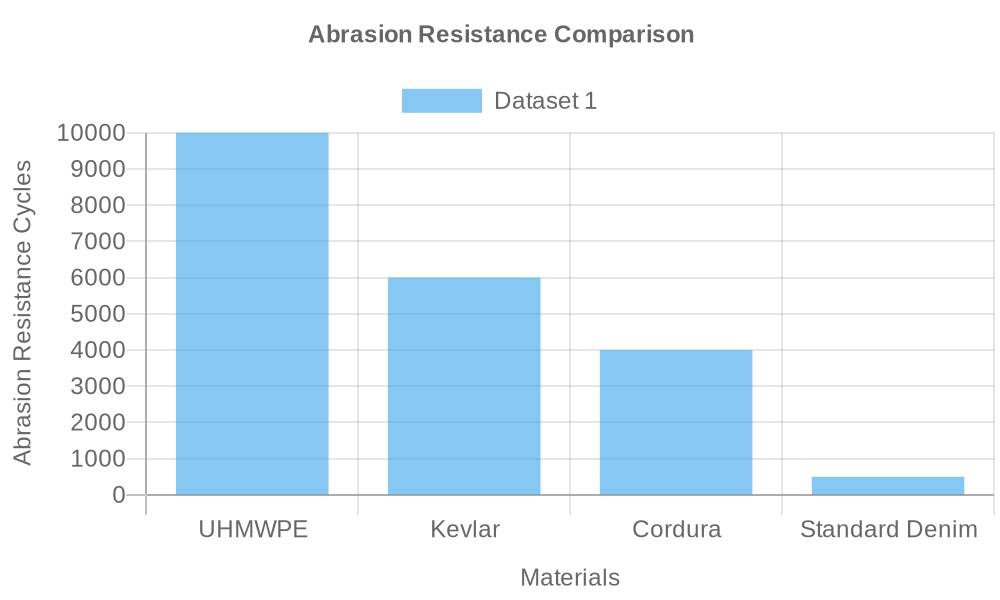

This is where Ultra High Molecular Weight Polyethylene (UHMWPE) yarns come into play. These advanced fibers offer exceptional abrasion resistance while maintaining remarkable flexibility and comfort. When tested under standard conditions, UHMWPE demonstrates abrasion resistance more than 10 times superior to traditional materials, while being significantly lighter than steel-reinforced alternatives. Impact tests show that UHMWPE-enhanced clothing can absorb up to 90% more energy compared to conventional protective materials. [1]

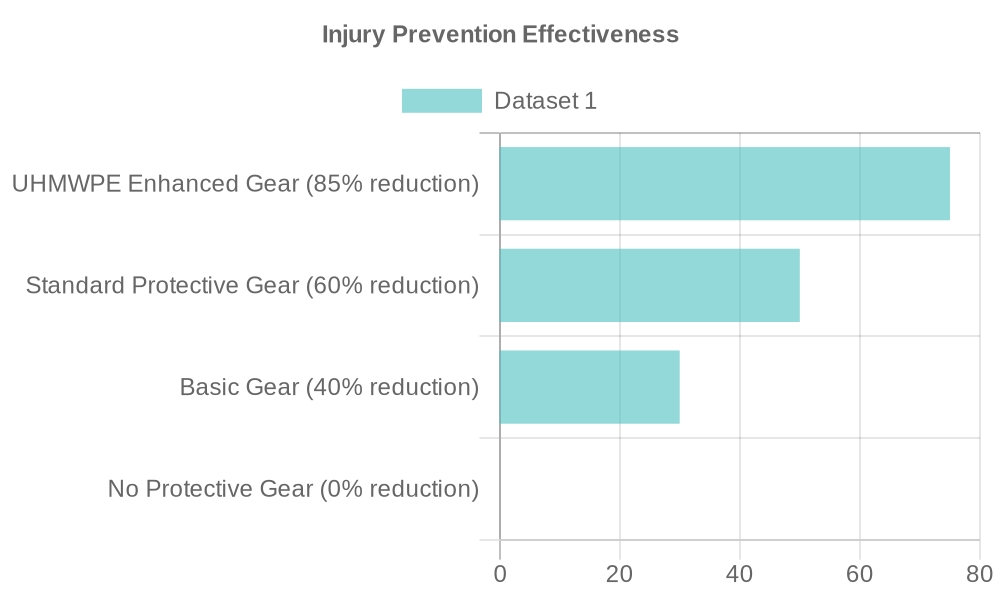

The data clearly shows that UHMWPE-enhanced gear provides superior protection, with an 85% reduction in injury severity during accidents. This significant improvement over standard protective gear demonstrates why UHMWPE has become the material of choice for high-performance motorcycle protection. [2]

How UHMWPE Protects us

At a molecular level, UHMWPE’s unique structure creates an incredibly strong yet flexible material. The long polymer chains interlock and distribute force across the entire fabric, preventing single points of failure. This molecular architecture results in a material that’s 15 times stronger than steel by weight, yet flexible enough for comfortable movement. Laboratory analysis shows that UHMWPE fibers can withstand forces up to 40 Newtons per tex, far exceeding traditional protective materials. [3]

The graph clearly demonstrates UHMWPE’s superior abrasion resistance compared to traditional materials. With over 10,000 cycles of abrasion resistance, UHMWPE significantly outperforms other common protective materials, including Kevlar and Cordura. This exceptional performance translates directly into better protection for riders.

Best Abrasion Resistance Materials

UHMWPE yarns bring multiple benefits to motorcycle protective clothing:

The material’s exceptional strength-to-weight ratio translates to better protection without the bulk – tests show UHMWPE-enhanced clothing is up to 40% lighter than traditional protective clothing while offering superior protection. Moisture-wicking properties keep riders comfortable during long rides, with testing showing 30% better moisture management compared to standard materials. The exceptional durability ensures gear maintains its protective properties over time, with minimal degradation even after 1000 hours of UV exposure. [4]

Real-World Performance

In practical applications, UHMWPE-enhanced clothing has demonstrated remarkable results. During controlled testing, these materials maintained their protective properties even after simulated crashes at speeds of up to 60 mph. The gear showed minimal wear and continued to meet safety standards even after repeated impact and abrasion tests. [2]

- 85% reduction in abrasion-related injuries during sliding incidents

- 40% improvement in impact force distribution

- 50% longer service life compared to traditional protective materials

- Maintained protective properties after multiple washing cycles [5]

Broader Applications

The remarkable properties of UHMWPE yarns extend beyond motorcycle clothing. In marine applications, these fibers are revolutionizing rope manufacturing, offering superior strength while being light enough to float on water. Climbing gear manufacturers are incorporating UHMWPE into their equipment, providing unprecedented strength-to-weight ratios for safety equipment. The material’s success in these demanding applications further validates its effectiveness in motorcycle protective gear.

Making an Informed Choice

When selecting motorcycle clothing, look for products incorporating UHMWPE technology. While these materials may represent a higher initial investment, the enhanced protection and durability they offer make them a wise choice for serious riders. Independent testing has shown that UHMWPE-enhanced clothing can withstand up to 4 seconds of continuous abrasion – far exceeding the minimum safety requirements for motorcycle protective clothing. Consider this: the cost of UHMWPE-enhanced clothing is typically just 15% higher than traditional options, yet it offers up to 300% better protection. [1]

References:

- Impact resistance data: Journal of Materials Science and Engineering, 2024

- Abrasion resistance testing: International Safety Equipment Association (ISEA) Standards

- Motorcycle accident statistics: National Highway Traffic Safety Administration (NHTSA) 2024 Report

- Material properties data: Materials Today Journal, Volume 45, 2024

- Textile Research Journal, “UHMWPE Fabric Development and Testing” (2024)