In the world of performance textiles, the microscopic architecture of fibers plays a crucial role in determining how materials perform under various conditions. While traditional round fibers have served as the industry standard, advanced cross-sectional modifications are creating new possibilities in textile performance and functionality.

The Science Behind Shape Innovation

Modern fiber engineering operates at the microscopic level, where the cross-sectional shape of each fiber can significantly impact overall material performance. These modifications create specific performance characteristics by manipulating how fibers interact with moisture, air, and heat – the three key elements that determine comfort and performance in technical textiles.

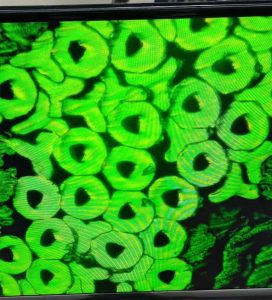

OY Section: The Perfect Marriage of Warmth and Moisture Management

The OY Section represents a breakthrough in fiber technology, combining hollow fiber (O) with Y-shaped channels. The hollow core creates microscopic air pockets that function similarly to double-pane windows, trapping air for superior insulation. This technology has been successfully implemented in advanced materials like aerogel-enhanced fibers and Infracycle materials.

The Y-shaped channels create a sophisticated moisture transport system. These micro-channels increase the surface area for moisture distribution by up to 250% compared to traditional round fibers, leading to significantly faster evaporation rates and improved thermal regulation during high-intensity activities.

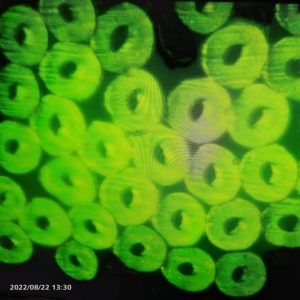

8C Microporous: Advanced Moisture Management

The 8C cross-sectional structure represents a significant advancement in moisture management technology. Its unique groove structure creates a three-dimensional pathway system that generates a four-fold siphon effect. This design enables:

Enhanced capillary action for superior moisture wicking

Increased surface area for faster evaporation

Better air circulation through micro-channels

Improved thermal regulation through evaporative cooling

In performance testing, 8C Microporous fibers demonstrate up to 30% faster moisture-wicking capabilities compared to conventional materials, making them ideal for high-intensity activities where sweat management is crucial.

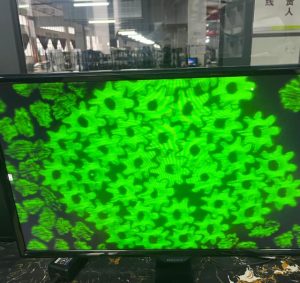

8C Microporous Enhanced with Cooling Masterbatch: 8C Pro

Advanced Synergistic Design

The integration of cooling masterbatch with 8C cross-sectional fiber creates a dual-action cooling system:

- Physical Cooling (8C Microporous)

- Unique 8C groove architecture creates enhanced capillary action

- Four-fold siphon effect accelerates moisture transport

- Three-dimensional moisture pathway system

- Increased surface area for rapid evaporation

- Chemical Cooling (Masterbatch Technology)

- Cooling masterbatch particles embedded in fiber matrix

- Active cooling through endothermic reaction

- Prolonged cooling effect through controlled release

- Even distribution throughout the fabric

Working Mechanism

Immediate Cooling Response

When body temperature rises during intense exercise:

- The cooling masterbatch activates at 28°C

- 8C channels begin active moisture transport

- Dual cooling effects work simultaneously:

- Chemical cooling from masterbatch

- Evaporative cooling through moisture management

Sustained Performance

The system maintains effectiveness through:

- Continuous moisture wicking via 8C channels

- Gradual release of cooling agents

- Enhanced air circulation through groove structure

- Maintained fabric structure even when wet

Performance Advantages

The integration of 8C microporous and cooling masterbatch(8C Pro) delivers remarkable temperature management capabilities. Within minutes of activity, wearers experience a noticeable temperature drop of 2-3°C, with the cooling effect sustained for up to 4 hours of intense exercise. The technology ensures even temperature distribution throughout the garment, effectively eliminating uncomfortable heat spots that typically occur during vigorous movement.

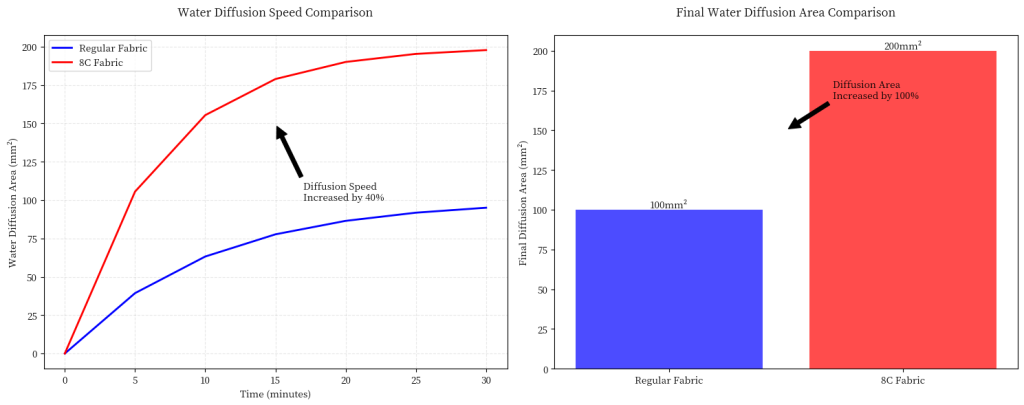

In terms of moisture control, this advanced fiber system demonstrates superior performance with moisture wicking speeds 40% faster than conventional fibers. The enhanced surface area creates a 200% larger moisture spread zone, significantly reducing the uncomfortable clinging sensation common during exercise. The rapid moisture distribution also contributes to notably faster drying times post-activity, enhancing both comfort and practicality.

Comfort reaches new heights with this innovative technology. Users experience a gentle cooling sensation without the jarring cold shock effect often associated with cooling fabrics. The balanced cooling distribution across the entire garment ensures consistent temperature regulation, while the sophisticated moisture management system minimizes post-exercise chill, maintaining comfort throughout varying activity intensities.

Ideal Applications

This advanced textile technology proves particularly valuable across diverse athletic scenarios. In high-intensity sports such as marathon running, indoor cycling, and HIIT training, the fabric’s superior cooling and moisture management properties enable athletes to maintain optimal performance levels. The technology excels in racquet sports, where rapid temperature regulation during intense bursts of activity is crucial for maintaining focus and endurance.

The benefits extend significantly to outdoor activities, making it an ideal choice for summer hiking, rock climbing, and mountain biking enthusiasts. The sustained cooling effect proves particularly valuable during extended periods of outdoor exercise, where environmental temperatures can pose additional challenges to performance and comfort.

Professional athletes and trainers find exceptional value in this technology during competitions, training sessions, and instruction. The consistent performance and reliable comfort allow fitness professionals to focus entirely on their activity without distraction from temperature or moisture-related discomfort. Personal trainers and fitness instructors particularly appreciate the extended durability and consistent performance throughout long days of multiple training sessions.

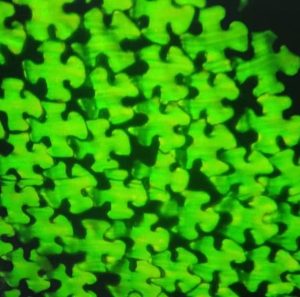

Cross Section: Enhanced Stability and Comfort

Cross-sectional fibers with 4T-shaped profiles provide unique benefits through their geometric configuration. The structure creates micro-spaces between fibers that enhance breathability while maintaining fabric integrity. This design particularly excels in:

- Dimensional stability under stress

- Enhanced ventilation through structured air channels

- Improved insulation efficiency through trapped air pockets

- Better compression recovery

Specialized Applications in Outdoor Equipment

Sleeping Bags and Insulation

In sleeping bags and insulation layers, specific cross-sectional modifications have revolutionized performance:

- Hollow Four-Channel Fibers

- Used in premium synthetic insulation

- Creates multiple air pockets for enhanced thermal efficiency

- Maintains warmth even when compressed

- Offers up to 20% better thermal resistance compared to solid fibers of the same weight

- Trilobal Fibers for Outer Shells

- Enhances water repellency through surface tension manipulation

- Creates micro-air gaps for improved breathability

- Provides natural UV protection through light reflection

- Reduces fabric weight while maintaining durability

- Multi-Channel Structures for Mid Layers

- Combines moisture management with thermal regulation

- Features 6-8 continuous channels for optimal moisture transport

- Creates thermal bridges for efficient heat distribution

- Maintains performance under compression and movement

Technical Outerwear

Advanced cross-sectional designs in technical outerwear incorporate:

- Profiled Moisture Management

- Y-shaped channels in base layers for direct skin contact

- 8C structures in mid-layers for maximum moisture transport

- Hollow fibers in outer layers for thermal protection

- Thermal Regulation Systems

- Combination of hollow and channeled fibers

- Strategic placement of different cross-sections

- Variable density structures for different body zones

- Active moisture transport combined with thermal barriers

Performance Metrics

Modern outdoor equipment utilizing modified cross-section fibers shows impressive performance improvements:

- Up to 40% better moisture-wicking capability

- 25-30% improved thermal efficiency

- 15-20% weight reduction without performance loss

- Enhanced durability through better fiber integration

Environmental Impact and Sustainability

The evolution of cross-sectional fiber modification has also led to more sustainable manufacturing processes:

- Reduced material usage through improved efficiency

- Lower energy consumption in production

- Enhanced product longevity

- Better recyclability through mono-material construction

Future Developments

Current research is focusing on:

- Adaptive Cross-Sections

- Shape-shifting fibers that respond to temperature

- Moisture-activated channel systems

- Variable performance based on conditions

- Bio-Inspired Structures

- Mimicking natural fiber structures like wool

- Incorporating biomimetic principles for enhanced performance

- Development of sustainable bio-based materials

- Smart Integration

- Combining modified cross-sections with smart materials

- Integration of sensing capabilities

- Active response to environmental conditions

Conclusion

The continued evolution of fiber cross-section modification demonstrates how microscopic engineering can create macroscopic performance benefits. As technology advances, we can expect even more sophisticated solutions that combine enhanced performance with sustainable practices, leading to the next generation of outdoor and performance textiles.