How PCM Yarn works?

PCM filament yarn functions through microencapsulated phase change materials embedded within synthetic fiber structures. When body temperature rises above the PCM’s melting point, these microcapsules absorb excess heat energy, converting from solid to liquid state. As temperature drops, the PCM solidifies, releasing stored heat energy back to the body, creating an active thermal buffering system at the fiber level.

Featured

Smart Temperature Adaptation

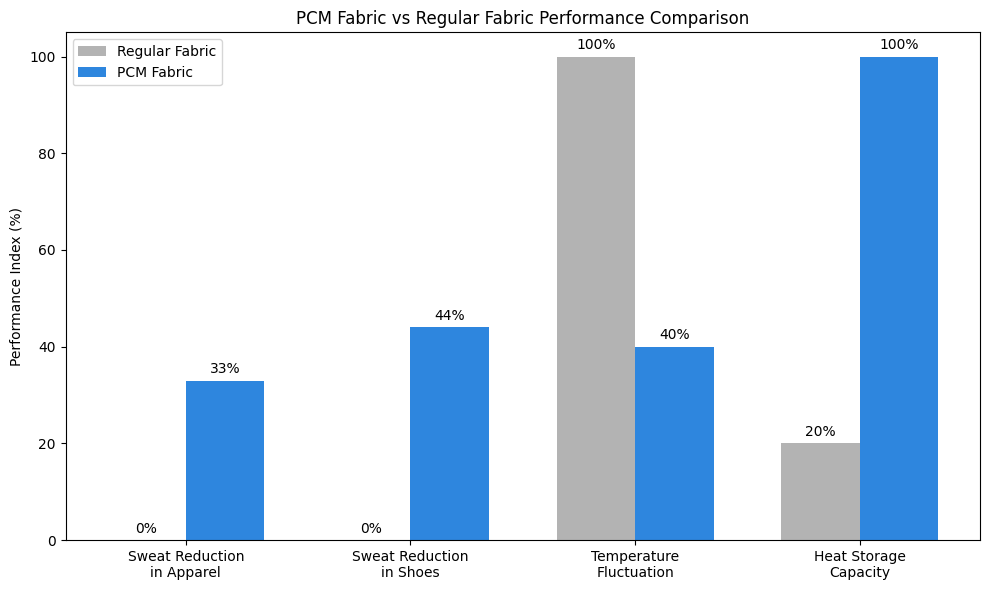

PCM actively manages body temperature through phase transition, absorbing excess heat during high activity and releasing stored thermal energy when body temperature drops.

PCM creates a responsive microclimate by transitioning between solid and liquid states at specific temperatures, providing automatic thermal buffering without external power.

Moisture Management Integration

PCM works alongside moisture-wicking properties to enhance overall comfort and thermal regulation effectiveness.

PCM Thermoregulation Yarn Applications

PCM yarn enhances thermal performance in diverse textile applications. With its temperature-regulating properties, PCM yarn creates high-performance sportswear for intense activities, protective gear for extreme weather conditions, and specialized outdoor equipment. Applications include winter sports apparel, military uniforms, bedding materials, casual wear, and technical workwear. The adaptive thermal management system particularly benefits activities with varying intensity levels and temperature fluctuations, from skiing to urban commuting.

Reviews

There are no reviews yet.